- Description

- Technical Parameter

- Other Instructions

- Ordering

Effectiveness and characteristics:

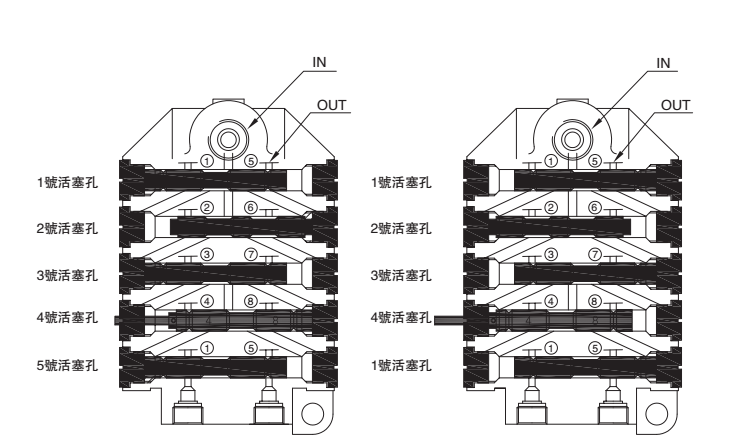

The progressive butter distributor is an advanced and reasonably structured oil distributor. The dispenser can be used in medium and wide temperature conditions it can with manual electric and pneumatic pump etc. the single lubrication system applicable to all kinds of small and medium sized machine and punching machine plastic machinery sub distributor or large single lubrication system and similar applications of the ideal products.

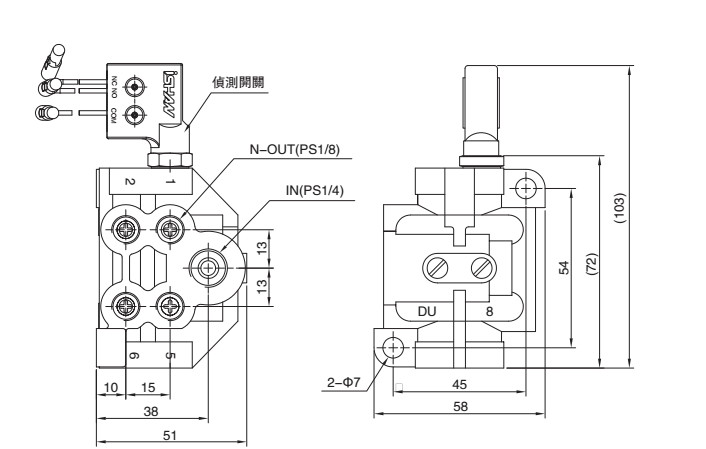

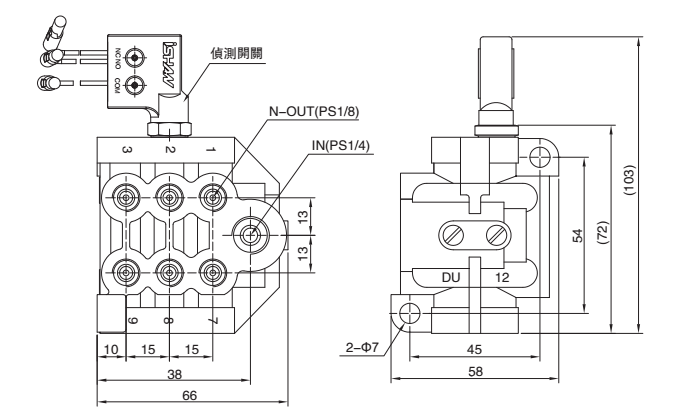

A group of DU distributors can normally provide 4 6 8 10 or 12 lubrication points. The DU distributor has only one specification of 0.3cc/cy.

Note: for the outlet of the distributor no oil outlet can be blocked.

Otherwise it will affect its normal work and damage the distributor.

| Type | Product No. | Detection switch | Export number | Theoretical spitting amount (cc/cy) | Weight (g) |

| DU-4T | 20210 | X | 4 | 0.3 | 310 |

| DU-4R | O | ||||

| DU-6T | X | 6 | 310 | ||

| DU-6R | O | ||||

| DU-8T | X | 8 | 310 | ||

| DU-8R | O | ||||

| DU-10T | X | 10 | 420 | ||

| DU-10R | O | ||||

| DU-12T | X | 12 | 420 | ||

| DU-12R | O |

Specifications and technical parameters:

1 maximum nominal pressure: 80kgf/cm2

2 standard displacement: 0.3cc/cy.

3. Application of grease: 000# to 1#

4 the working environment temperature: -10 degrees C 60.

5. The maximum cycle rate of starving plunger pair with mechanical cycle indicator: 60cy/min.

6. The maximum circulatory rate of the plunger pair: 200cy/min.

7. The number of lubricants for each group is 4 6 8 10 12..

8 the best pipe diameter and length of the distributor output: 4mm long 0.5-2.5m.

9 valve material: aluminum alloy.