Comparison of common standard and special single end mechanical seal for rotating jet pump

2018-03-10

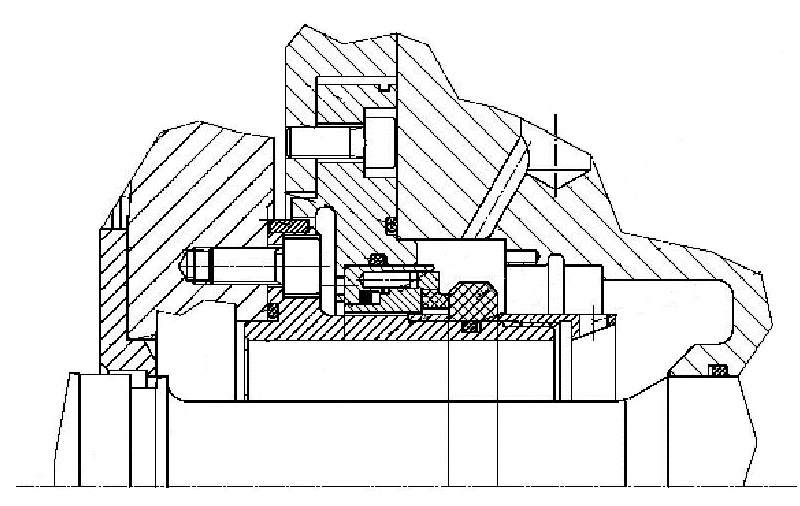

From the chart (three-dimensional structure of the working principle of reference map) can be seen in conventional rotating jet pump drive shaft and the inlet and outlet is separated, the drive shaft is positioned in the pump seal, a different side of the machine, so the manufacturers in the design of rotating jet pump mechanical seal is used different layout form. In order to be able to use the ordinary machine seal, the rotor sleeve is added to the rotor, which is used to fix the moving ring of the machine seal, and there are also a non shaft sleeve specially designed for the rotating jet pump.

Sketch map of ordinary single end mechanical seal

As shown, the mechanical seal in the operation process of the medium into the rotor cavity through the space between the sleeve and the receiving tube, friction immersed in medium mechanical seal, the dip in the medium position of the side friction medium flow is poor, can not run the heat generated by the mechanical seal well by pumping take away the media, through the washing machine sealing machine sealing can improve the working environment, but the washing liquid and pumping medium mixed limit flushing mode selection.

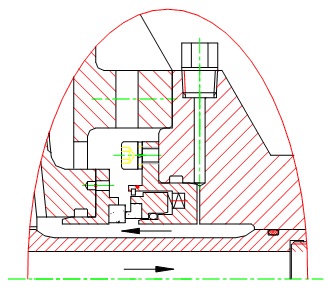

A schematic diagram of a single end mechanical seal for a rotating jet pump

As shown in the operation process of the medium through the sealing side friction between the pair and the receiving tube space into the rotor chamber of the mechanical seal, immersed in the medium side side friction mechanical seal, the other side away from the medium, due to the immersion in the medium position of the side friction medium has been due to the pump work continuously flow, mechanical seal operation can generate heat through the media continue to take to improve the sealing work environment, compared with the ordinary single mechanical seal, mechanical seal of the structure under the same conditions the working environment is better than the ordinary single mechanical seal, when the ordinary single mechanical seal needs to be washed to the mechanical seal does not necessarily need washing. At the same time, the mechanical seal is specially designed for the rotary jet pump. From the structure diagram, we can see that the selection of the mechanical seal rinse scheme is more flexible, and we can choose the inner flushing scheme, and we can also choose the external washing plan that the washing liquid is not mixed with the pump medium.